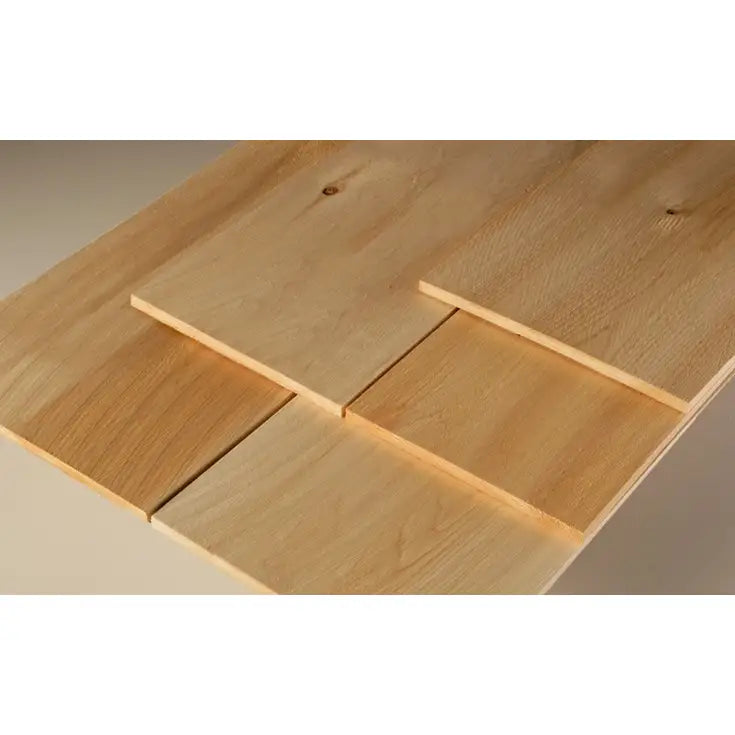

Box Sidewall Select 16" White Cedar R&R Shingles - SBC Cedar

Please call for a custom shipping quote for pallet orders.

Details

Upgrade your home's appearance with White Cedar Shingles from SBC Cedar. This highly-resistant species resists decay and insects, making it ideal for exterior siding. Cedar's warmth, variations in shades, and rich texture is often imitated, but cannot be matched. R&R shingles by SBC Cedar are precisely squared and are graded on both sides for fast installation without compromising quality.

Options:

• Natural

• Factory-Finished Enviro Bleach, a hybrid low-VOC weathering agent with fungicide that gives the shingles a natural, silvery-gray appearance.

Features:

• Precision-cut for 2 parallel sides and a perfectly squared butt

• 15% wider than the industry standard, with a minimum width of 3 7/16"

• Shingles are reversible as they are graded on both sides.

• Kiln-dried through dehumidification for more stable, less brittle shingles

• Durable finish for factory-finished shingles from exclusive dipping process

• Easy installation with an embossed nail line on every shingle

• White Cedar is highly resistant to mildew and decay

• SBC covers Factory-Finished Shingles with their 30 Year Peace of Mind Limited Warranty.

SBC Sidewall Select AB Grade:

Sidewall Select AB grade allows no imperfections on the exposed surface. By blending Extra A and Clear B grades, Sidewall Select shingles area wider for a faster installation and better appearance. SBC cedar shingles are graded on both faces. SBC grade standards exceed CSA 0118.2-F08 (C2018).

Enviro Bleach Details:

Enviro Bleach is a revolutionary hybrid stain offering the appearance of oil-based weathering agents along with the environmental advantages of latex finishes. It is produced in accordance with the highest standards governing volatile organic compounds (VOC), and contains a mildewcide agent to reduce mildew. Results can vary depending on exposure to sun, rain, and geographic orientation.

Shingle Details:

• Length: 16"

• Grade: Sidewall Select AB

• Side and Edge Cuts: Rebutted & Rejointed (R&R) - R&R shingles are trimmed for parallel edges with the butts sawn at right angles.

• Drying: Kiln-Dried through dehumidification

• Exposure Options: 4"-5"

• Width: Shingles can vary from 3-7/16" to 12"

• Thickness: 3/8" at the butt to 1/16" at the tip

• Use Area: Sidewall application only

Coverage Rates:

Shingles vary in the amount of completed coverage they will yield based on the width of exposure you choose. Exposure is the exposed surface of the shingle once installed. Shingles boxes will generally cover more area with a wider exposure.

Estimating Cedar Shingles:

1. Measure the amount of square footage you have to cover.

2. Find the amount of coverage per box at your desired exposure using the chart above.

3. Divide the square footage of coverage needed by the square footage per box value from the chart.

Example: You wish to cover 200 square feet of sidewall using a 5" exposure. The chart shows that 5" exposure should yield 25 square feet of coverage per box. Divide 200 sf by 25, which results in 8 boxes needed.

Product Resources:

• Technical Specifications - SBC Natural R&R Cedar Shingles

• Technical Specifications - SBC Factory-Finished R&R Cedar Shingles

• How to Install White Cedar Shingles

• How to Maintain Cedar Shingle Siding

• SBC Factory-Stained Cedar Shingles Warranty

• SBC Cedar Product Catalog

• SBC Cedar In Stock Color Options

Specifications

More Information

|

Fastener Selection: Installation: Fastener Application: Finishing: |

Reviews

Product Questions

| Product Details | |

|---|---|

Grade |

|

Wood Species |

|

Finish |

|

Drying |

|

Shingle Length |

|

Thickness Average thickness of shingle/shake at the butt (bottom) end

|

|

Width |

|

Side and Edge Cuts |

|

Edges Parallel |

|

| Installation Details | |

Application Type |

|

Standard Sizing |

|

Exposure - Sidewall Refers to options on the length of the shake that can be exposed to the weather. Wider exposures yield more square feet of coverage per bundle.

|

|